The use of zinc sheet metal can be found throughout a wide range of industries because its unique properties make it an ideal choice for many different projects.

Additionally, zinc metal sheets are relatively easy to work with and can be cut, drilled, or otherwise shaped to meet your needs.

With that in mind, the following are a few things you should know about zinc sheet metal.

It was originally designed for industrial applications, including roof flashing, cathode protection, chemical resistance, water resistance, engraving, and more due to its durability and resistance to corrosion.

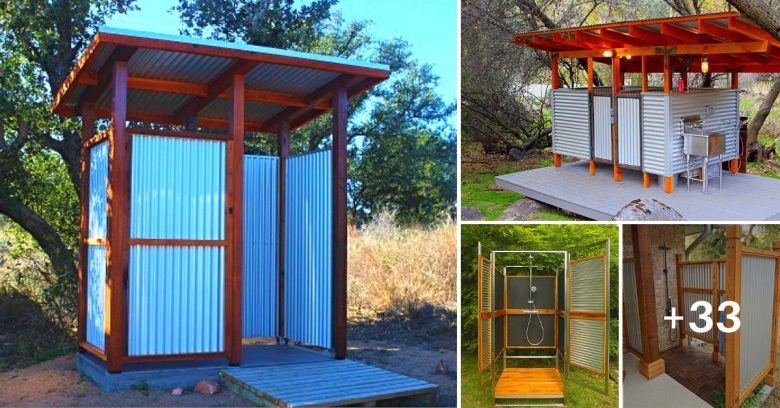

Today, zinc sheet metal is commonly used in the construction industry for roofing and cladding as well as gutters and downspouts.

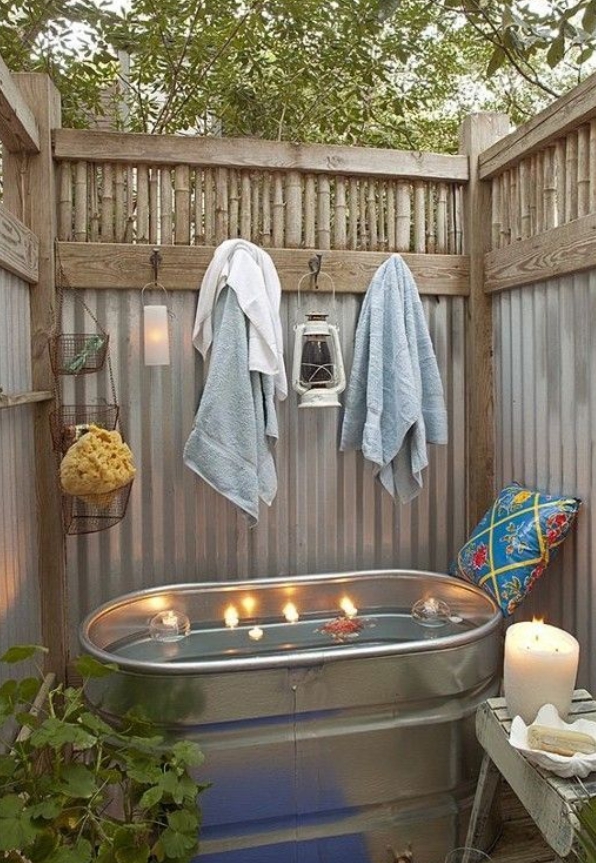

It’s also used fairly often in the commercial industry for every thing from countertops to appliances because of how nonporous the metal is.

Zinc is commonly used in the automotive industry as well, as it can be used to create parts that are resistant to rust and corrosion.

Additionally, because it can be easily cut into a variety of shapes and sizes, zinc metal sheets are used for decorative elements, such as decorative moldings.

Zinc sheet metal is available in a variety of thicknesses and sizes. Because of how durable and flexible zinc sheet metal is, it can be rolled into thin sheets without losing any of its strength.

As such, it can be produced in thinner sheets (lower gauges) than a lot of other types of metals.

When it comes to finishing zinc sheet metal, there aren’t a lot of options. It’s very non-porous, which means paint won’t adhere to its surface.

However, you can buff and polish zinc sheet metal to create a refined shine. Zinc metal sheets will also develop a patina (which can create a light gray to green appearance) over time as a result of exposure to moisture and other elements.

Some manufacturers sell pre-weathered zinc metal sheets that already have already developed this patina.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Credit: Pinterest